US 'energy dominance' will depend upon CO2

Billions of barrels of oil could be unlocked, but only if thousands of miles of CO2 pipeline are laid

Welcome to Carbon Risk — helping investors navigate 'The Currency of Decarbonisation'! 🏭

If you haven’t already subscribed please click on the link below, or try a 7-day free trial giving you full access. By subscribing you’ll join more than 5,000 people who already read Carbon Risk. Check out the Carbon Risk backstory and find out what other subscribers are saying.

You can also follow on LinkedIn, Bluesky, and Notes. The Carbon Risk referral program means you get rewarded for sharing the articles. Once you’ve read this article be sure to check out the table of contents [Start here].

Thanks for reading Carbon Risk and sharing my work! 🔥

Estimated reading time ~ 11 mins

“…CO2 is going to be much needed for the US for our extended energy independence.”

- Vicki Hollub, CEO of Occidental Petroleum

Enhanced oil recovery (EOR) involves injecting high-pressure CO2, sometimes alternated with pulses of water, into an oil reservoir, scrubbing the existing pathways within the rock, enabling a more efficient flow of oil. By pushing more crude to the surface, EOR can recover up to 60% of the oil remaining in a reservoir.

Incremental oil recovery from EOR was estimated to be around 250,000 barrels per day in 2022/23, according to the U.S. CO2 EOR Survey. This is the additional amount of oil extracted from oil reservoirs using EOR techniques, beyond what could be recovered through primary and secondary recovery methods.

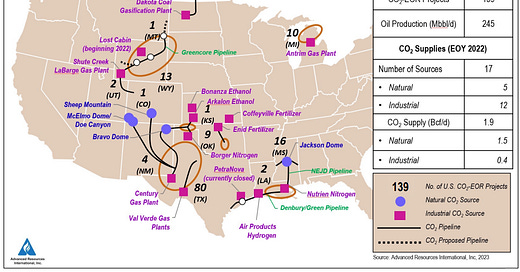

About 35 Mt of CO2 is currently used for EOR in the US, with more than three-quarters sourced from natural underground CO2 deposits located nearby, with the remainder derived from industrial emitters such as ethanol plants. Overall, this works out at an average utilisation rate of 0.4 tonnes of CO2 per barrel of oil extracted.1 2

US EOR oil production has dropped by about 20% since it peaked in 2017 at just over 300,000 barrels per day. The main factors behind the decline were the drop in the price of oil, a shortage of industrial sourced CO2, and a move towards maximising the use of horizontal drilling by oil producers.

EOR lowers the carbon intensity of US crude production

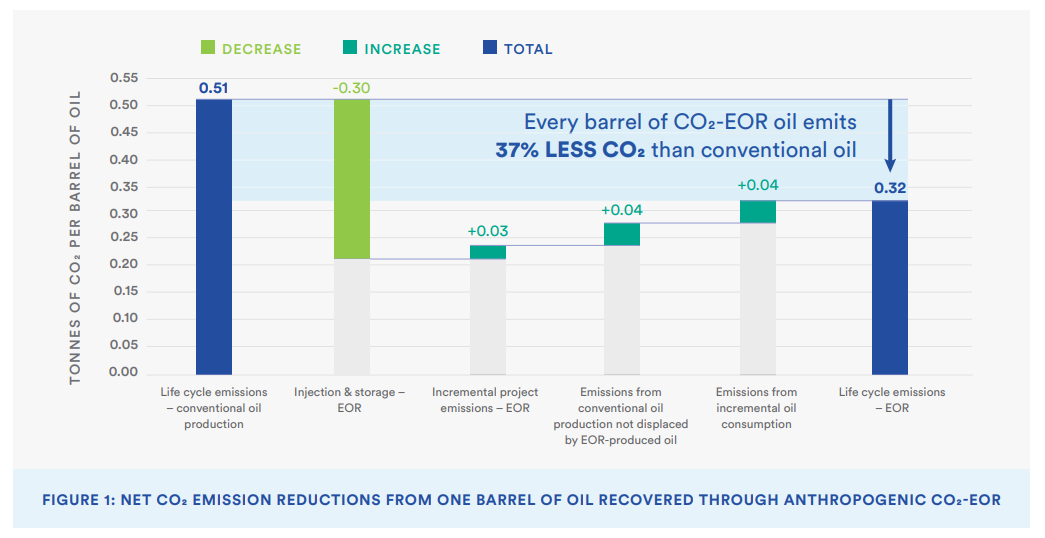

Analysis by the Clean Air Task Force, drawing on lifecycle analysis (LCA) by the International Energy Agency (IEA) compared the “well-to-wheel” emissions of EOR produced oil versus conventional oil and found that EOR results in a significant reduction in emissions per barrel.3

To start, the CATF estimates that one barrel of conventional oil emits 0.51 tonne of CO2 per barrel. EOR involves injecting CO2 helps to release crude oil trapped in the pores of the source rock, in the process permanently trapping the CO2. Recovery of every barrel of oil produced through EOR typically involves injecting and utilising 0.3-0.4 tonnes of CO2 per barrel. Hence, relative to conventional oil production, EOR lowers the well-to-wheel emissions to 0.21 tonnes of CO2 per barrel.

However, EOR operations have higher process emissions compared to conventional oil. The separation and recycling of CO2 involves an additional 0.03 tonnes of CO2 emissions per barrel of oil produced. The CATF estimates that EOR produced oil displaces around 84% of the emissions from conventional oil production, leaving emissions higher by 0.04 tonnes of CO2 per barrel. Finally, the increase in oil production due to EOR - and the associated drop in the price of oil - results in an increase in consumption, and a corresponding rise in emissions (0.04 tonnes of CO2 per barrel).

Overall, the CATF estimates that EOR results in a 37% reduction in emissions per barrel, compared to conventional oil production. Another study, this time employing a dynamic LCA, measured the net CO2 released over time. It found that EOR oil projects are typically net carbon-negative at first (up to anywhere between 6 and 18 years depending on the processes used), but then as oil production declines, the EOR project moves towards becoming net carbon-positive. 45

During the course of EOR some CO2 does come back to the surface, but given the expense, operators typically recycle it and then reinject it underground. Oil producers need to balance the cost of paying to separate the CO2 from the production stream and inject it back into the oil reservoir, versus sourcing CO2 from natural or industrial sources, switching from one source to another when a certain price is reached. For example, the cost of sourcing CO2 from industrial sources is estimated to be in the range of $20-$45 per tonne.

Over the lifetime of a project around 90-95% of the CO2 injected into the ground is permanently trapped in the geological formation. However, about three-quarters of the CO2 sequestered underground is from naturally occurring CO2, casting doubt on the low-carbon intensity of EOR produced oil. One way that oil producers can alleviate these concerns is by ramping up the proportion of CO2 that they use captured from industrial sources, or by using CO2 removed directly from the atmosphere using direct air capture (DAC).

Industrial carbon capture could unlock billions of barrels

The potential for EOR to unlock billions of barrels of oil is immense. In 2020, the US Geological Survey (USGS) estimated that 29 billion barrels of oil might be produced using EOR technologies in amenable US conventional oil reservoirs. The USGS estimated that 8.4 Gt CO2 could be stored (retained) in the assessed oil reservoirs following the application of EOR.