Repost: The emergence of the carbon economy

Why construction materials are likely to dominate future CO2 demand

Welcome to Carbon Risk — helping investors navigate 'The Currency of Decarbonisation'! 🏭

If you haven’t already subscribed please click on the link below, or try a 7-day free trial giving you full access. By subscribing you’ll join more than 3,000 people who already read Carbon Risk. Check out what other subscribers are saying.

You can also follow my posts on LinkedIn. The Carbon Risk referral program means you get rewarded for sharing the articles. Once you’ve read this article be sure to check out the table of contents.

Thanks for reading Carbon Risk and sharing my work! 🔥

Estimated reading time ~ 12 mins

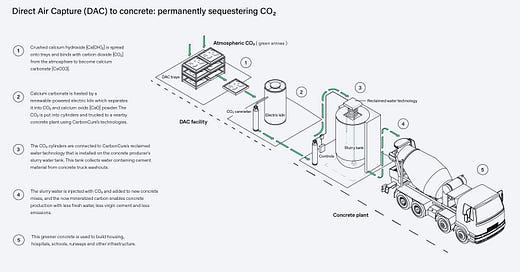

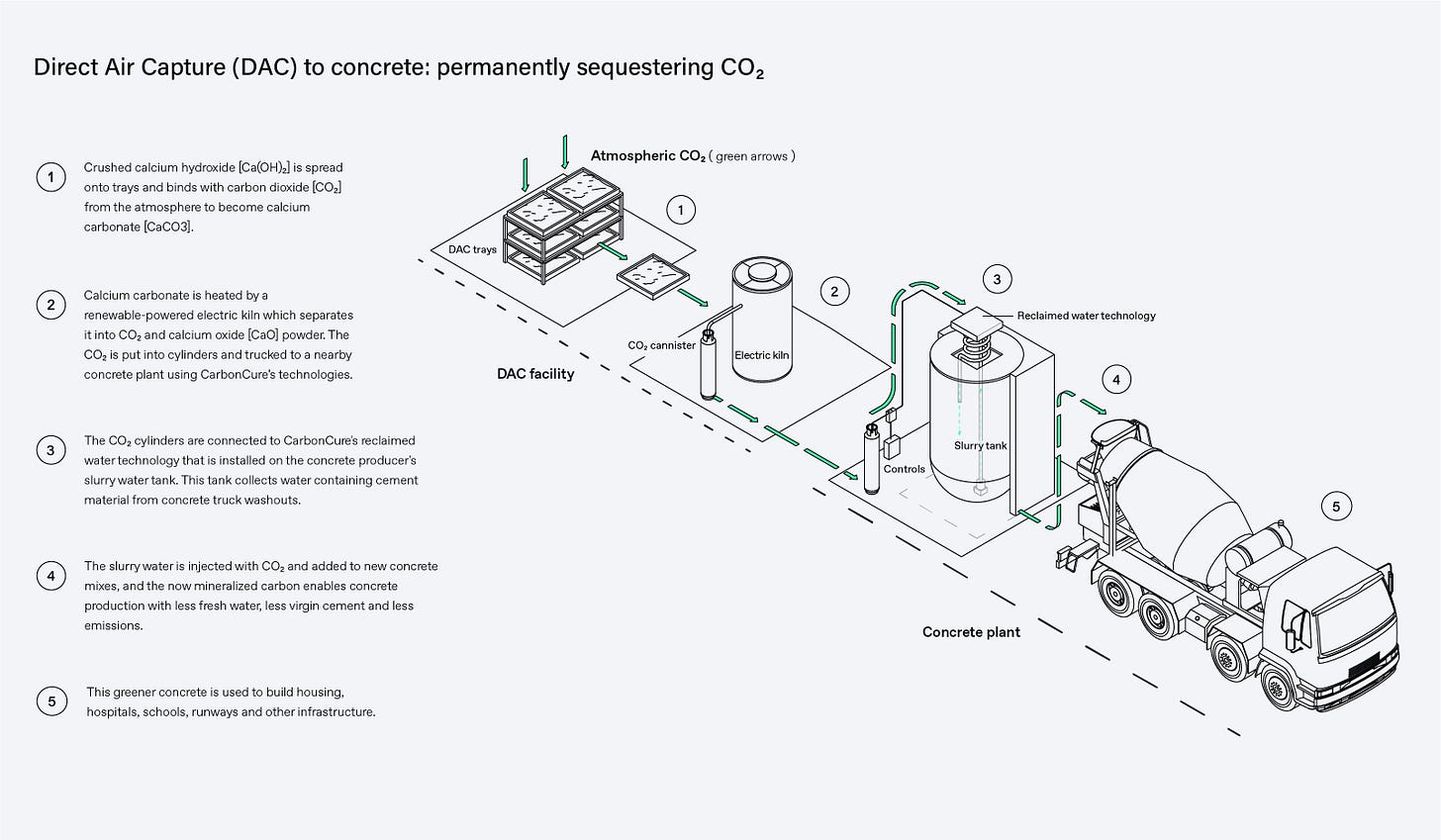

In early February, two North American companies announced that they had successfully incorporated CO2 captured from the atmosphere using Direct Air Capture (DAC) into freshly produced concrete. Heirloom, which owns America’s only operational DAC plant delivered 30 kg of CO2 captured from the air around San Francisco to a nearby concrete facility, where CarbonCure’s carbon mineralisation solution was used to sequester it into concrete.1

Injecting CO2 reduces the overall carbon footprint associated with producing concrete by 5-15% depending on the process used. Not too bad given the industry accounts for around 6-8% of global CO2 emissions. However, the real bonus is concrete’s carbon storage properties as the CO2 can be locked up for centuries, even if the concrete is demolished.

The announcement - which represents a world first - could revolutionise the global market for carbon, capture and storage (CCS), beyond its current reliance on government subsidies and those companies with the foresight to back them with pre-purchases and offtake agreements.

Scaling this technology faces some significant barriers, not least of which is growing global DAC capacity. However, if construction materials are likely to dominate future demand for CO2 then DAC developers need to question whether they are building their facilities in the right place. Concrete demand is closely linked with urbanisation and so emerging economies in Asia and West Africa may represent the best opportunities for growth.

Lets dive in.

We tend to think of carbon dioxide (CO2) as a bad thing: a pollutant, a ‘negative externality’ in economics speak, something to be rid of, and certainly not something of value.

However, CO2 is a valuable input for many industrial processes.

Global CO2 demand was estimated to be ~230 Mt in 2015, according to the International Energy Agency (IEA).

The fertiliser industry is the largest consumer (57%), with 130 Mt CO2 used in the production of urea in 2015. The oil and gas industry accounted for around one-third (34%) of demand, utilising 70-80 Mt of CO2 for enhanced oil recovery (EOR).

Other commercial applications include food and beverage production (14 Mt CO2, 6%), followed by metal fabrication, cooling, fire suppression, and in support of plant growth in greenhouses (< 10Mt CO2, 4%).

China is the major market for CO2, accounting for about 28% of global demand in 2020, followed closely by North America with 27%, and Southwest Asia with 11%. In terms of market share, demand has pivoted away from traditional end markets in North America and Europe, and towards China and emerging markets in Asia.

In 2019 the IEA projected global CO2 demand would increase to 250 Mt CO2 in 2020 and reach 272 Mt CO2 by 2025. This is based on the assumption that demand continues to rise at a trend rate of 1.7% per annum, led by urea and EOR. However, as we’ll see later, demand for CO2 could grow much faster than this if other applications are able to utilise additional streams of captured CO2.