Welcome to Carbon Risk — helping investors navigate 'The Currency of Decarbonisation'! 🏭

If you haven’t already subscribed please click on the link below, or try a 7-day free trial giving you full access. By subscribing you’ll join more than 4,000 people who already read Carbon Risk. Check out what other subscribers are saying.

You can also follow my posts on LinkedIn. The Carbon Risk referral program means you get rewarded for sharing the articles. Once you’ve read this article be sure to check out the table of contents [Start here].

Thanks for reading Carbon Risk and sharing my work! 🔥

Estimated reading time ~ 11 mins

Every month or so I repost an article from the Carbon Risk archives. The subscriber base for Carbon Risk has grown significantly over the last few years and so many of my current readers probably haven’t seen some of the earlier articles. Many of the posts are arguably even more relevant now than the day they were first published. Following that theme, this repost focuses on the carbon intensity of lithium.

Lithium miners are failing to live up to their climate pledges.

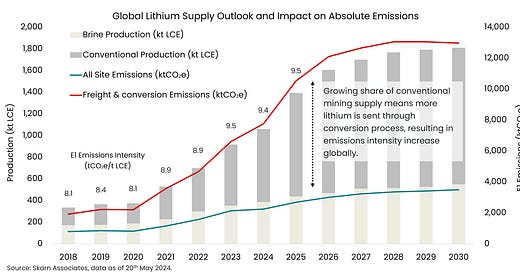

Instead of acting as a beacon for the responsible mining of energy transition commodities, and cutting their emissions, the carbon intensity of global lithium supply is increasing. Lithium carbonate production jumped by over 30% between 2022 and 2023 to 917 thousand tonnes. Expansions at existing mines, particularly carbon intensive conventional mining involving spodumene, accounted for 84% of the increase.

New conventional lithium mines are expected to open between now and the end of the decade. These will typically be some 30% less carbon intensive than older mines as they make use of power grids with a greater share of renewable energy. Nevertheless, the rate of progress is not sufficient to prevent overall lithium supply from becoming even more carbon intensive by the end of the decade.

A richer, less carbon intensive stream of lithium may be close at hand. Later this decade the first wave of electric vehicles will reach the end of their life. Recent breakthroughs in recycling technology mean that old batteries may become an even more important source of lithium than extracting it from rock and beneath the salt lakes.

Demand for commodities essential to the green energy transition are expected to rise fourfold by 2040 if we are to reach the goals of the Paris Agreement, i.e., climate stabilisation at “well below 2°C global temperature rise”. In order to achieve net-zero globally by 2050, six times more commodity inputs will be required by clean energy technology in 2040, according to the International Energy Agency (IEA).

However, the average growth in commodity demand does a disservice to the growth requirements of certain niche metals essential to the energy transition. For example, demand for nickel, cobalt and graphite are all projected to grow 20-25 times under the IEA’s Sustainable Development Scenario (SDS) by 2040.1

Lithium demand is projected to grow almost twice as fast, with the IEA estimating that the requirement for lithium from clean energy technology will need to rise 42 times by 2040, primarily reflecting the expected growth in demand for electric vehicles (see Carbonomics returns).

Despite serving an overwhelming positive environmental outcome, lithium cannot escape its own carbon footprint being scrutinised by battery producers, automobile manufacturers and investors.

The environmental performance of lithium miners and refiners is likely to become a key differentiator in the lithium industry, with strong leadership on emissions reduction rewarded by institutions allocating capital to the sector.

So, how is lithium extracted and processed, what are the main sources of emissions, and what can be done to minimise them?