What price decarbonised shipping?

A carbon price will have powerful knock-on effects on global ship supply

Shipping is scheduled to be included in the EU ETS from January 2023. That can’t come soon enough. Emissions from maritime transport (international, domestic and fishing), accounts for 3% of annual global carbon emissions.

The problem is the fuel burnt by ships. Known as marine fuel oil, or bunker fuel it is a sludgy byproduct of oil refineries. Each tonne of marine fuel burned emits around 3.2 tonnes of carbon dioxide into the atmosphere.

Recall that the overarching target behind the ‘Fit for 55 package’ is to cut EU emissions by 55% by 2030, compared with 1990 levels and then to reach net-zero by 2050. Maritime transport will face the same overarching targets as other sectors of the economy included under the EU ETS.

This article looks at the likely carbon prices required to decarbonise the shipping sector, and the knock-on impacts on the sector from which investors may be able to benefit from.

How will the EU push shipping to decarbonise?

Emissions from all voyages between ports in the European Economic Area and at berth in EEA, plus 50% of emissions from international inbound voyages and 50% of emissions from international outbound voyages will be covered under the scheme.

Shipping will not receive free allocations. Instead their obligation will gradually increase over time. An obligated maritime entity will have to buy allowances for 20% of its emissions in 2023, increasing to 40% in 2024, 70% in 2025 and 100% of emissions in 2026.

According to a recent Lloyd’s List analysis, 81.2 million tonnes of CO2 of the total 119.9 million tonnes of CO2 emitted in EEA-related voyages during 2020 would have been covered by the EU ETS. This will mean demand for carbon allowances should grow from 16.2 million in 2023 to 81.2 million in 2026, assuming total carbon emissions from the sector remain flat.

Each shipping company will be assigned to a specific EU member state authority that will oversee their compliance with the ETS. As with every other obligated emitter, the failure of a shipping company to surrender the right amount of allowances by the end of April 30 of the following year will result in a fine of €111 per tonne of CO2 equivalent it did not have sufficient allowances for. Furthermore, should a shipping company not comply for two consecutive years then it could be denied entry from EU ports, if the member state that oversees its compliance choose to do so.

To stimulate the uptake of sustainable maritime fuels and zero-emission technologies the Fuel EU Maritime proposal sets a maximum limit on the greenhouse gas intensity of energy used on-board by a ship. Shipping companies will have to improve the GHG intensity of the fuels they use by

2% from January 1, 2025,

6% from 2030,

13% from 2035,

26% from 2040,

59% from 2045, and

75% from 2050.

How high do carbon prices need to be decarbonise shipping?

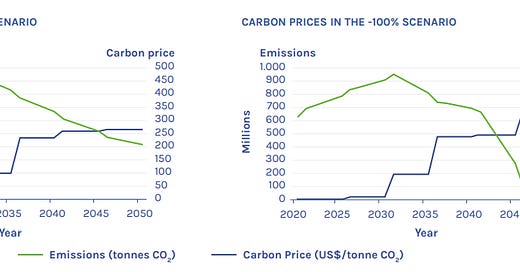

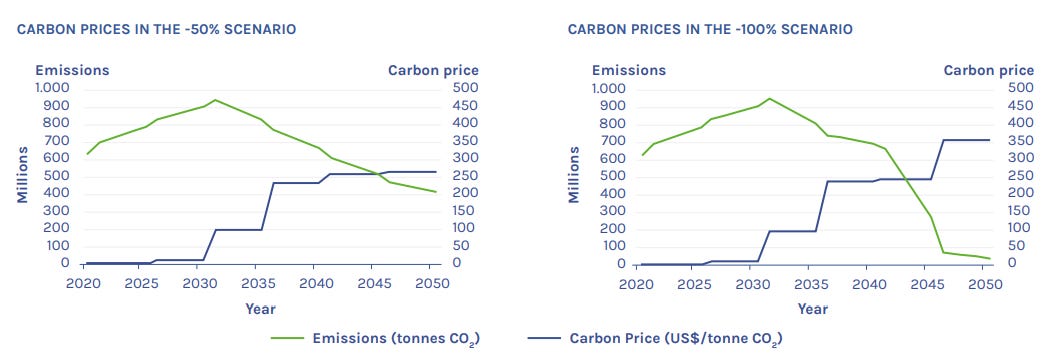

According to a report published by the Getting to Zero Coalition, an industry group led by the think tank Global Maritime Forum (GMF), marine fuel oil will need to face an average carbon price of almost $200 per tonne (€180 per tonne) in order to decarbonise shipping by 2050. Crucially though, GMF believe the carbon price needs to be much higher in order to drive decarbonisation:

In order to achieve 50% GHG emissions reduction by 2050 compared to 2008 (-50% scenario), the carbon price level averages US$173/tonne CO2. For a 2050 target of full decarbonisation (-100% scenario), the average carbon price would only need to be slightly higher: around US$191/tonne CO2. In both scenarios, according to the model, the price level begins at US$11/tonne CO2 when introduced in 2025 and is ramped up to around US$100/tonne CO2 in the early 2030s at which point emissions start to decline. The carbon price then further increases to US$264/tonne CO2 in the -50% scenario, and to US$360/tonne CO2 in the -100% scenario.

As of late January 2022 the EU Dec-22 futures price is ~€90 per tonne ($100 per tonne). At the current carbon price the tax would equal $320 per tonne of fuel oil (3.2 tonnes of CO2 per tonne of fuel oil), adding roughly 50% to the total cost of marine fuel oil (~$600 per tonne excl. carbon tax). Clearly, at an average price of carbon of almost $200 per tonne the total cost of marine fuel would almost double.

Both scenarios assume that the carbon burden on shipping is introduced at a low level initially and is gradually scaled up. The GMF report assumes a much slower pace of carbon price escalation for the sector than that accounted for in the ‘Fit for 55’ proposals in which its obligation increases over the course of four years from one-fifth to 100%. At this point shipping would face the full carbon price, whatever value it is at the time.

Immense switching costs point to higher carbon prices

Barriers to switching to zero carbon alternatives in the shipping sector are immense, and unlike other sectors much of the investment needs to go into infrastructure that individual shipping companies have little or no control over - land based infrastructure such as ports. The report estimates that some 87% of the $1.4-1.9 trillion in investment required to decarbonise needs to be directed at land based infrastructure. This includes hydrogen production, ammonia synthesis and storage/distribution.

The presence of market barriers means that the carbon price needs to rise much further than that required to simply meet the cost of abatement. The price signal needs to be high, and stay there if it is to do anything to alter behaviour and incentivise the investment required.

As such, while the report outlines carbon price trajectories required to meet a 50% cut and 100% cut, I believe it fails to take sufficient account of expectations and the immense barriers to decarbonisation in the sector. A more realistic carbon price profile is for prices to rise much faster, much sooner and then gradually taper off over the rest of the period as the infrastructure and cleaner fuels are brought online. As with other sectors of the economy covered by the EU ETS it is useless if carbon prices only reach the required level on the eve of the year you need to meet the targets. By then it will be too late.

In any market where there are significant bottlenecks, prices need to rise far higher than the market imagines before demand and supply can begin to adjust and eventually reach some sort of stable equilibrium. Decarbonising the shipping sector is no different.

The knock-on impact on vessel supply

Carbon markets don’t operate in isolation. Investors can benefit from the knock-on supply issues they create in supply chains. One such potential beneficiary is likely to be those first mover ship owners that have already decarbonised their fleet, and correctly anticipated the future fuel requirements and have the scale to be flexible when infrastructure capacity is uncertain.

Regulatory uncertainty is a key factor that can impact on the supply of vessels. In the absence of clarity, or to appease regulators, ship charters may seek to reduce their sailing speed, so called ‘slow-steaming’. Reducing the speed at which ships travel by 10% could reduce fuel usage by almost one-third. However, the knock-on effect of this is to reduce the supply of ships available to the market than would otherwise have been the case. This means that other operators can benefit from higher freight rates.

The International Marine Organization (IMO) sets regulations for the international shipping industry. As such shipping pollution falls under its purview. However, despite plenty of talk, up until now there has been little or no action to actually decarbonise the industry. The most recent regulations (IMO 2020) were introduced to shift vessels from high-sulphur to low-sulphur fuel; this either required ship owners to introduce sulphur scrubbers or undergo an engine retrofit that would allow them to use low-sulphur fuel, both of which are expensive.

The next set of regulations (IMO 2030) go even further and are designed to sharply reduce the shipping industry’s carbon intensity. These regulations are aimed at forcing older less-efficient tankers off the market but might have the unintended consequence of keeping the existing fleet in service for longer.

Similarly, the inclusion of maritime shipping in the EU ETS is likely to force the EU to use modern vessels, and relegate older, more polluting ships to elsewhere in the world. While this shifts the problem elsewhere it will help to determine the future investment strategy of ships owners looking to renew their fleet.

Uncertainty over environmental regulations means that it is unclear what technological solution to pursue. For example, it’s unclear whether hydrogen, ammonia or another candidate will provide the best low carbon option at an affordable cost. This would result in ship owners delaying placing orders, which might lead to a tightening in the supply of ships.

Other factors affecting the long term supply of dry bulk vessels and crude & product tankers

Over the very long term, the supply of dry bulk and crude & product vessels is typically closely related to changes in world trade for the underlying commodities. In a situation where ship owners match demand, which over the very long run they will, then you would expect freight rates to track shipping costs plus some margin. But again it’s not quite that simple. Vessel owners face a number of problems in matching vessel supply and the demand for shipments.

First, owners are likely to have the greatest confidence in expanding their fleet at or near the top of the business cycle. High freight rates and easy access to credit provides the perfect backdrop for shipping companies to expand their fleet. By the time those ships come into force the demand for ships may have plummeted, and as the supply of ships has expanded the freight rate they are able to achieve will also plummet. Vessel owners need to balance the composition of their fleet (e.g. the proportion of Capsizes, Panamaxes dry bulk vessels) to the likely trade routes.

Second, vessel owners need to consider the cost of a new vessel and the likely time it will take to enter service. Although it typically takes around 4 years between order and delivery of a new vessel, bottlenecks at the shipyards might add delays to the delivery date. Between 2001 and 2008 global shipyard capacity was unable to keep up with the demand for seaborne commodity trade sparked by China joining the World Trade Organisation (WTO) which helped support dry bulk rates (the BDI rose 10-fold during this seven year period). In this example, contracts were made with delivery dates 5-6 years into the future. However, by the time those vessels were delivered there was an excess supply and dry bulk freight rates collapsed (the BDI fell by almost 95% in the second half of 2008).

Investors also need to consider other ways in which bottlenecks might occur. Shipyards don’t just build dry bulk vessels; space is limited and so dry bulk ship owners compete with orders for container ships, tankers, LNG vessels and other dry bulk orders. For example, shipyards might be booked up with the construction of container ships and so have little or no capacity to construct dry bulk carriers. This kind of bottleneck increases the pricing power of the shipyard, adding to the potential cost borne by the ship company.

Third, given that the average age of a dry bulk carrier is around 20-25 years, vessel owners also need to consider the benefits of keeping older ships in service versus the benefits from scrapping them. This includes the freight rates they can generate while in service (scrapping is likely to be low if high freight rates are expected to continue), the price of marine fuel (older ships tend to be less fuel efficient and more polluting), and the cost of scrap steel (high prices may lead to more scrapping).