In the summer of 2025, a facility in Texas is due to come on stream that could mark a step change in the business of carbon removal.

The facility, known as DAC-1 is operated by Occidental Petroleum and is located in the Permian Basin, Texas. DAC-1 will extract 0.5 Mt CO2 per year directly out of the air and then either be pumped underground for permanent storage, or it will be used for Enhanced Oil Recovery (EOR).

The project was due to begin in 2024 but supply chain issues have pushed the start date back one year. Eventually, the plant will be able to extract 1 Mt CO2 per year.

Up until now I’ve tended to focus on nature-based forms of carbon removal (e.g. afforestation, mangroves, etc.), and hybrid techniques that combine both technology and natural processes to capture carbon from the atmosphere (e.g. biochar and BECCS). In contrast, Direct Air Capture (DAC) is the only form of carbon removal that is completely technology based (see Char grilled: Why biochar is the most promising carbon removal technology).

Despite concerns from some quarters that DAC is a dangerous diversion, deflecting attention from cutting emissions first before resorting to carbon sequestration, rolling out DAC capacity is crucial if we are to decarbonise a number of hard-to-abate sectors, such as aviation and potentially other sectors too (see Blending in: Decarbonising air travel with 'sustainable' fuel).

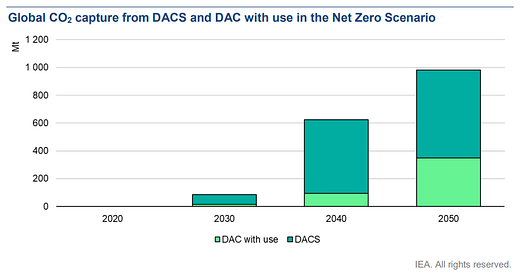

Furthermore, unlike other forms of carbon removal, DAC offers the potential to be almost infinitely scalable. The resource requirements in terms of land are minimal compared with BECCS or biochar. Access to zero carbon baseload power is the main factor determining it’s effectiveness, and as innovation hots up, and the number and size of DAC plants increases, their energy efficiency is expected to improve significantly.

Lets dive in.